- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

Web Menu

- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

Product Search

Exit Menu

Which Industries and Applications Commonly Use LG Multistage Centrifugal Pumps?

LG multistage centrifugal pumps are designed to deliver high pressure and consistent flow rates across various industrial applications. Unlike single-stage pumps, they contain multiple impellers mounted on a single shaft, which increases the head without sacrificing efficiency. This makes them ideal for applications that require high-pressure pumping of liquids, water distribution, and process fluids.

These pumps are widely recognized for their durability, energy efficiency, and adaptability in handling clean and slightly contaminated fluids. They offer smooth operation, reduced vibration, and minimal maintenance requirements, making them a preferred choice for engineers and plant operators.

Water Supply and Distribution Systems

One of the most common applications of LG multistage centrifugal pumps is in municipal water supply systems. Their ability to maintain consistent pressure over long pipelines ensures reliable water distribution for residential, commercial, and industrial zones.

These pumps are also used in booster stations to enhance water pressure in high-rise buildings and irrigation networks. Their multistage design allows them to handle varying flow rates while maintaining energy efficiency and reducing operational costs.

Industrial Process Applications

LG multistage centrifugal pumps are extensively used in industrial processes that require high-pressure fluid transfer. Industries such as chemical manufacturing, pharmaceuticals, and food processing rely on these pumps to move process liquids through complex piping systems without pressure loss or flow disruption.

Their robust construction and corrosion-resistant materials enable handling of various fluids, including mildly abrasive or chemically treated water, ensuring safety and reliability in sensitive operations.

Chemical and Petrochemical Industries

In chemical and petrochemical plants, LG multistage centrifugal pumps are used to circulate solvents, acids, and process water. Their multistage configuration allows high-pressure pumping while maintaining controlled flow rates, which is essential for chemical reactions and cooling processes.

The pumps’ adaptability to different materials, such as stainless steel or alloyed casings, ensures resistance to corrosion, extending the service life even under continuous operation in aggressive chemical environments.

Power Generation and Boiler Feed Applications

Power plants frequently employ LG multistage centrifugal pumps as boiler feed pumps and for condensate transfer. These pumps provide the necessary high pressure to deliver water into boilers, maintaining consistent steam generation and efficiency.

Their precision-engineered impellers reduce cavitation risk, which is critical for maintaining pump reliability in high-temperature and high-pressure environments. Efficient operation in these settings minimizes energy consumption and operational costs.

HVAC and Building Services

In heating, ventilation, and air conditioning (HVAC) systems, LG multistage centrifugal pumps are used for chilled water circulation, hot water supply, and pressurization systems. They ensure uniform water flow and pressure, enhancing system efficiency and occupant comfort.

The pumps’ quiet operation and minimal vibration make them suitable for building applications, while their ability to handle variable flow rates ensures energy savings in large-scale HVAC systems.

Water Treatment and Desalination

Water treatment plants rely on LG multistage centrifugal pumps for high-pressure transfer of raw, treated, and recycled water. In desalination plants, these pumps provide the necessary pressure for reverse osmosis membranes, ensuring efficient freshwater production.

Their corrosion-resistant construction and high efficiency reduce maintenance requirements and operational downtime, which is essential for continuous water treatment operations.

Irrigation and Agricultural Applications

In agriculture, LG multistage centrifugal pumps are widely used for irrigation systems, providing uniform water pressure across extensive fields and greenhouses. Their ability to deliver high head over long distances ensures that water reaches all areas evenly.

These pumps also support fertilizer injection and fluid transfer in agro-industrial facilities, benefiting from precise flow control and reliable operation in outdoor environments.

Firefighting and High-Pressure Water Supply

LG multistage centrifugal pumps are employed in firefighting systems where high pressure and reliability are crucial. They can maintain strong water jets over long distances and multiple outlets, ensuring safety and compliance with fire protection standards.

In addition to firefighting, these pumps are used in high-rise buildings, industrial complexes, and municipal systems that require stable high-pressure water delivery.

Common Applications Overview

- Municipal water supply and booster stations

- Industrial process fluid transfer

- Boiler feed in power generation

- HVAC chilled and hot water circulation

- Water treatment and desalination

- Irrigation and agricultural pumping

- Firefighting and high-pressure supply

Comparative Advantages of LG Multistage Pumps

| Feature | LG Multistage Pump | Single-Stage Pump |

| Maximum Head | High (multiple impellers) | Limited |

| Energy Efficiency | Optimized for variable flow | Moderate |

| Operational Stability | Excellent | Moderate |

| Maintenance | Low | Higher |

Conclusion

LG multistage centrifugal pumps are versatile and essential for industries that demand high-pressure, reliable, and energy-efficient pumping. Their broad application across municipal, industrial, agricultural, and firefighting systems underscores their importance in modern infrastructure.

By selecting the right LG multistage pump for specific applications, engineers and operators can ensure optimal performance, reduced operational costs, and long-term reliability, making these pumps a critical component in fluid management systems worldwide.

Related Products

-

TD high-efficiency and energy-saving circulating pump cast iron impeller

Cat:TD High-efficiency And Energy-saving Circulating Pump Accessories

TD Energy Efficient Circulation Pump Cast Iron Impeller is an importan...

See Details -

Cutting sewage pump

Cat:Sewage Pump

Cutting sewage pump is a kind of sewage pump, also called cutting pump...

See Details -

Sewage pump hanging cover

Cat:Sewage Pump Accessories

Installed on the upper part of the sewage pump unit, it is used for li...

See Details -

Sewage pump casing

Cat:Sewage Pump Accessories

The casing of the sewage pump unit plays a role in protecting the inte...

See Details -

Sewage pump foot plate

Cat:Sewage Pump Accessories

Components mounted on the bottom of the sewage pump unit to support th...

See Details -

LG multistage pump cast iron impeller

Cat:LG Multi-stage Pump Accessories

Cast iron impeller is one of the key components of the pump, which pre...

See Details -

LG multi-stage pump water bearing gland

Cat:LG Multi-stage Pump Accessories

Water bearing gland is the gland for fixing the water bearing, which s...

See Details -

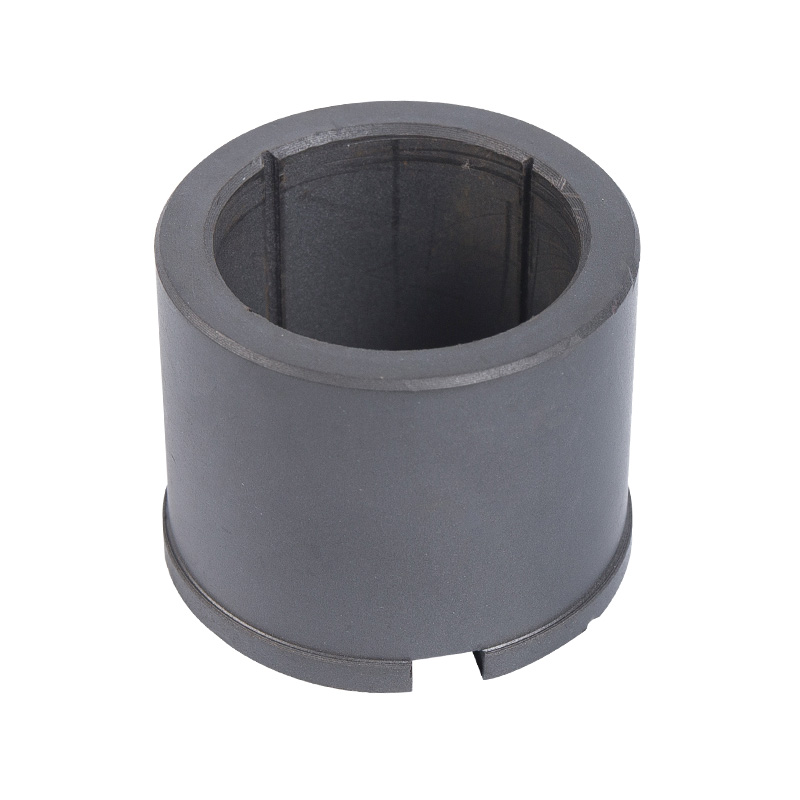

LG multi-stage pump water bearing

Cat:LG Multi-stage Pump Accessories

Water bearings are a special type of bearings commonly used in multi-s...

See Details -

B3/B35 Horizontal inverter motor

Cat:Inverter Electric Motor

Also known as base mounting, the motor is connected to the mounting da...

See Details -

Cooling Tower Circulation Pump

Cat:Cooling Tower Circulation Pump

The cooling tower circulation pump is key equipment in the cooling tow...

See Details

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

-

+86-0563-2251312

-

+86-0563-2251311

-

+86-139 6620 0379

-

-

No.43 Guohua Road, Guangde Economic Development Zone, Xuancheng City, Anhui Province, China