- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

Web Menu

- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

Product Search

Exit Menu

Why Are LG Multistage Centrifugal Pumps the Ultimate Solution for High-Pressure Fluid Systems?

In modern industrial and commercial operations, efficient and reliable fluid transfer is essential. Whether in water supply, HVAC systems, fire protection, or industrial processing, a dependable pump ensures consistent pressure and performance. Among the many types of pumps available, LG Multistage Centrifugal Pumps stand out for their exceptional pressure capability, energy efficiency, and versatility.

But what makes these pumps so popular across industries? Why do engineers and facility managers often choose LG multistage pumps over other designs? Let’s explore what sets them apart — from their working principle and structure to their applications, advantages, and future potential.

1. What Is an LG Multistage Centrifugal Pump?

An LG Multistage Centrifugal Pump is a horizontal, multistage, high-pressure pump designed for transferring clear water or other liquids with similar physical and chemical properties.

“Multistage” refers to the fact that the pump contains multiple impellers (or “stages”) arranged in series. Each impeller adds energy to the liquid, increasing its pressure as it moves through the stages. This design allows the pump to generate high pressure with relatively low power input, making it ideal for applications requiring strong water flow over long distances or at high elevations.

The “LG” designation typically refers to a specific model series known for reliable performance, compact structure, and quiet operation, widely used in water supply systems, boilers, cooling circulation, and firefighting setups.

2. How Does an LG Multistage Centrifugal Pump Work?

The operating principle of an LG multistage centrifugal pump is based on centrifugal force. Here’s how it works step by step:

- Liquid Inlet (Suction): Fluid enters the pump through the suction side into the eye of the first impeller.

- Energy Conversion (First Stage): The impeller rotates at high speed, imparting kinetic energy to the liquid and pushing it outward into the diffuser or volute casing.

- Pressure Increase (Multiple Stages): The fluid then moves into the next impeller, where it gains additional pressure. This process repeats across multiple impellers, each one adding more energy.

- Discharge (Outlet): Finally, the pressurized liquid exits the pump at the discharge port with significantly higher pressure than when it entered.

Each impeller acts like a “booster,” and when combined, the multiple stages produce a continuous and smooth high-pressure output, suitable for demanding fluid transfer operations.

3. Structural Design and Components

The LG Multistage Centrifugal Pump is engineered for durability, efficiency, and easy maintenance. Its core components include:

- Pump Body: Usually made of cast iron or stainless steel, providing strength and corrosion resistance.

- Impellers: Multiple impellers mounted on a single shaft, each precisely balanced to reduce vibration and noise.

- Diffusers: Direct fluid smoothly between stages, improving energy efficiency.

- Shaft: A stainless-steel shaft connects all impellers, ensuring alignment and durability.

- Mechanical Seal or Packing Seal: Prevents leakage between the pump and motor.

- Bearings: Support the shaft and minimize friction during operation.

- Base Plate and Coupling: Ensure stability and allow easy alignment with the motor.

The modular design makes maintenance simple — individual stages or impellers can be replaced without dismantling the entire unit.

4. Key Features of LG Multistage Centrifugal Pumps

What makes LG multistage centrifugal pumps stand out from other pumping systems? Their superior design brings a combination of performance, safety, and efficiency.

Main Features:

- High Pressure Output: Multiple impellers enable the pump to deliver significantly higher pressure than single-stage designs.

- Compact Horizontal Structure: Space-saving design, easy to install and maintain.

- Stable Operation: Precision engineering ensures low vibration and noise.

- High Efficiency: Optimized hydraulic design reduces energy consumption.

- Corrosion-Resistant Materials: Suitable for water and light chemical liquids.

- Wide Flow and Head Range: Adaptable for small to large-scale systems.

- Mechanical Seal Design: Ensures long-lasting, leak-free performance.

- Customizable Configuration: Available in various materials (cast iron, stainless steel, bronze) and pressure ratings.

These features make the LG series one of the most cost-effective and reliable multistage pump options on the market.

5. Applications of LG Multistage Centrifugal Pumps

The versatility of LG multistage pumps allows them to serve across many industries. Their ability to generate high pressure while maintaining efficiency makes them suitable for a wide range of uses:

1. Industrial Water Supply and Circulation

Used in manufacturing facilities, chemical plants, and power stations to circulate cooling or process water.

2. Boiler Feed Systems

Deliver high-pressure water to boiler systems, ensuring stable operation and steam generation.

3. Firefighting Systems

Provide powerful water jets through hydrants or sprinkler networks, ensuring effective fire suppression.

4. Building Water Supply

Commonly used in high-rise buildings, residential complexes, and hotels for pressure boosting and distribution.

5. Irrigation and Agriculture

Ensure steady water delivery for large-scale irrigation systems, even over long distances or uneven terrain.

6. HVAC Systems

Support chilled and hot water circulation in heating, ventilation, and air conditioning networks.

7. Water Treatment Plants

Used in filtration, reverse osmosis, and pressure boosting applications in water purification facilities.

These diverse applications demonstrate the adaptability and strength of the LG multistage centrifugal pump across multiple sectors.

6. Advantages of LG Multistage Centrifugal Pumps

Choosing an LG multistage pump offers several practical and economic benefits:

1. High Pressure Capability

Each impeller stage increases the head, enabling the pump to deliver water to high elevations or over long distances efficiently.

2. Energy Efficiency

Thanks to precise engineering, energy losses are minimized, resulting in lower operational costs.

3. Reliable Continuous Operation

Heavy-duty bearings and sealed designs allow for long-term, maintenance-free performance.

4. Compact and Space-Saving

The horizontal design requires less installation space, making it suitable for confined plant rooms.

5. Quiet Operation

Balanced impellers and smooth hydraulic flow reduce vibration and noise, providing a quiet working environment.

6. Easy Maintenance

The modular design allows easy disassembly for inspection or part replacement.

7. Versatility

Can handle different liquids — from clean water to light industrial fluids — across a wide range of temperatures.

8. Long Service Life

High-quality materials and robust construction ensure durability even under continuous or high-pressure operations.

Together, these benefits make LG multistage pumps a trusted choice for engineers and operators worldwide.

7. Technical Performance Parameters

While specifications vary by model, typical performance characteristics of LG multistage centrifugal pumps include:

- Flow Range: 3–200 m³/h

- Head (Pressure): Up to 300 meters or more

- Temperature Range: -15°C to +120°C

- Working Pressure: Up to 2.5 MPa (depending on stage count)

- Power Rating: 0.75–110 kW

- Speed: 2900 rpm (standard for 50 Hz AC motor)

These parameters make them suitable for medium to high-pressure applications where consistent flow and performance are essential.

8. Materials and Construction Options

Depending on the working fluid and environment, LG multistage pumps are available in several material configurations:

- Cast Iron: Standard option for clean water applications.

- Stainless Steel: Corrosion-resistant and ideal for slightly corrosive fluids or hygienic systems.

- Bronze Impellers: Used in marine or high-humidity environments.

- Carbon Steel or Alloy Steel: For high-temperature or high-pressure industrial applications.

Selecting the right material ensures compatibility, safety, and longevity of the pump in different working conditions.

9. Installation and Maintenance Guidelines

Proper installation and care are essential for maximizing performance and service life.

Installation Tips:

- Install the pump on a flat, vibration-free foundation.

- Ensure correct alignment between pump and motor shafts.

- Use flexible couplings to absorb slight misalignments.

- Keep suction piping short and straight to minimize losses.

- Always prime the pump before starting to prevent dry running.

Maintenance Practices:

- Regularly check for unusual noises or vibrations.

- Inspect seals and bearings for wear.

- Lubricate bearings according to manufacturer recommendations.

- Keep suction strainers and filters clean.

- Replace worn impellers promptly to maintain efficiency.

Following these best practices guarantees reliable performance and reduces downtime.

10. Comparing LG Multistage Pumps with Other Pump Types

How do LG multistage centrifugal pumps differ from other common pumps?

| Pump Type | Pressure Capability | Efficiency | Typical Use | Maintenance |

| Single-Stage Centrifugal Pump | Moderate | High | General water transfer | Easy |

| LG Multistage Centrifugal Pump | Very High | Very High | High-pressure systems | Moderate |

| Vertical Multistage Pump | High | Very High | Space-limited setups | Complex |

| Submersible Pump | Medium | Medium | Wells, drainage | Easy |

| Positive Displacement Pump | Very High | Low | Viscous fluids | Moderate |

This comparison highlights that LG multistage pumps strike the perfect balance between high pressure, efficiency, and practicality for clean water systems.

11. The Future of LG Multistage Pump Technology

With industrial automation and sustainability on the rise, the future of LG multistage pumps lies in smarter, greener designs:

- Intelligent Controls: Integration with variable frequency drives (VFDs) for automatic speed and pressure adjustment.

- Energy Optimization: High-efficiency motors that reduce electricity consumption.

- IoT Connectivity: Real-time performance monitoring for predictive maintenance.

- Lightweight Materials: Use of advanced composites for easier handling and installation.

- Eco-Friendly Manufacturing: Sustainable materials and reduced production emissions.

These innovations will further enhance the reliability, efficiency, and environmental performance of LG pump systems.

Conclusion: Power, Precision, and Reliability in One Pump

So, why are LG Multistage Centrifugal Pumps considered the ultimate solution for high-pressure fluid systems?

Because they combine engineering excellence, energy efficiency, and long-term reliability in one compact unit.

From high-rise building water supply to industrial boiler feed systems, these pumps deliver consistent performance even under the most demanding conditions. Their multistage design ensures superior pressure generation, while their robust construction guarantees years of trouble-free operation.

In a world that demands both performance and sustainability, the LG Multistage Centrifugal Pump stands as a true symbol of technological innovation and mechanical efficiency — driving progress one stage at a time.

Related Products

-

Vertical pipeline pump

Cat:Pipeline Pump

ISG series single-stage single-suction vertical centrifugal pump is a ...

See Details -

Horizontal pipeline pump

Cat:Pipeline Pump

ISW series single-stage single-suction horizontal centrifugal pumps ar...

See Details -

Horizontal pipeline pump body

Cat:Pipeline Pump Accessories

The pump body consists of two main parts: suction chamber and pressure...

See Details -

Cutting sewage pump

Cat:Sewage Pump

Cutting sewage pump is a kind of sewage pump, also called cutting pump...

See Details -

Sewage pump cast iron impeller

Cat:Sewage Pump Accessories

The impeller is the core component of a sewage pump, responsible for r...

See Details -

LG multistage pump cast iron impeller

Cat:LG Multi-stage Pump Accessories

Cast iron impeller is one of the key components of the pump, which pre...

See Details -

LG multi-stage pump shaft

Cat:LG Multi-stage Pump Accessories

The pump shaft is the key component to bear the rotational force and t...

See Details -

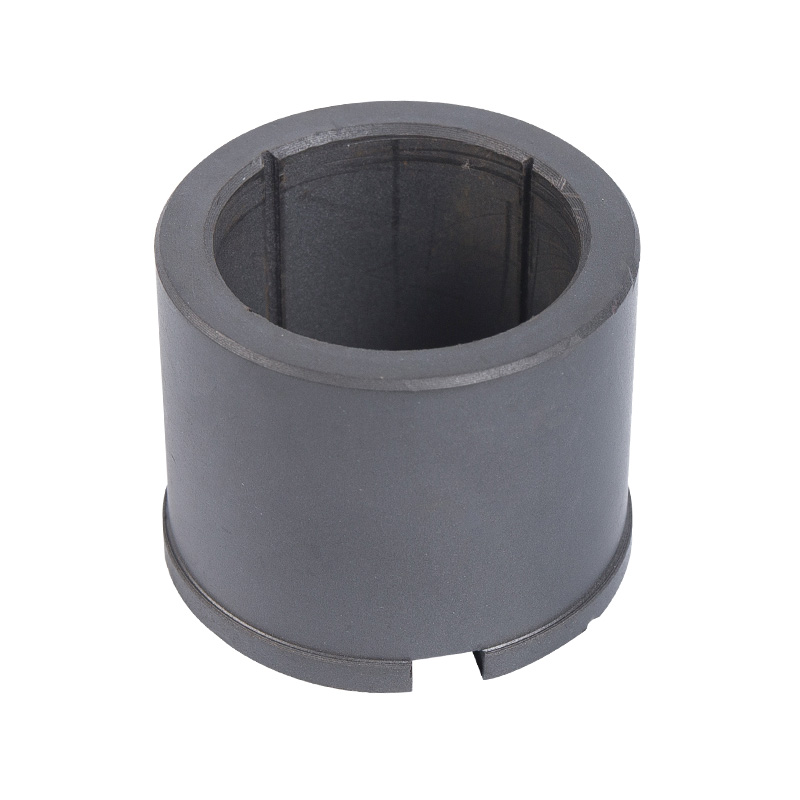

LG multi-stage pump water bearing

Cat:LG Multi-stage Pump Accessories

Water bearings are a special type of bearings commonly used in multi-s...

See Details -

Vertical motors

Cat:Ordinary Electric Motor

A conventional fixed-speed motor whose operating speed is usually cons...

See Details -

Finished rotor

Cat:Electric Motor Accessories

The rotor of a motor refers to the rotating part, which contains the r...

See Details

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

-

+86-0563-2251312

-

+86-0563-2251311

-

+86-139 6620 0379

-

-

No.43 Guohua Road, Guangde Economic Development Zone, Xuancheng City, Anhui Province, China