- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

Web Menu

- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

Product Search

Exit Menu

Which Industries Benefit Most from Cutting Sewage Pumps?

Sewage management is a critical component of modern industrial operations, municipal infrastructure, and environmental protection. Traditional sewage pumps often struggle with handling solid waste, fibrous materials, or debris that can clog or damage the system. This challenge has given rise to cutting sewage pumps, which are designed to handle difficult sewage applications efficiently by chopping solids and fibrous materials before pumping.

Cutting sewage pumps combine the functions of shredding and pumping, offering high reliability, efficiency, and durability. They have become essential in various industries where wastewater contains solid particles, fibers, or challenging debris. This article explores the industries that benefit most from cutting sewage pumps, their applications, and why these pumps are preferred over standard sewage pumps.

1. Municipal and Urban Wastewater Treatment

Municipal wastewater treatment facilities are responsible for processing sewage from residential, commercial, and industrial sources. Municipal sewage often contains a mix of organic waste, plastics, rags, and other solid debris.

1.1 Challenges in Municipal Sewage

- High volumes of wastewater with varying solid content.

- Presence of rags, sanitary products, plastics, and fibrous materials that can clog traditional pumps.

- Need for reliable and continuous operation to prevent backflow and overflow.

1.2 Role of Cutting Sewage Pumps

Cutting sewage pumps are designed with rotating blades or cutting mechanisms that shred solids before pumping, preventing clogging and ensuring smooth flow. Their applications in municipal systems include:

- Primary Wastewater Pumping: Moving raw sewage from collection points to treatment plants.

- Pre-Treatment Processes: Chopping solids before entering primary sedimentation tanks or screening systems.

- Stormwater and Combined Sewer Systems: Handling debris-laden water during heavy rains.

By efficiently managing solids, cutting sewage pumps reduce maintenance requirements, prevent downtime, and improve the overall efficiency of municipal wastewater systems.

2. Industrial Wastewater Management

Many industries generate wastewater containing solid particles, fibers, or viscous substances that can disrupt conventional pumping systems. Cutting sewage pumps are particularly beneficial in industrial applications due to their ability to handle challenging waste streams.

2.1 Food and Beverage Industry

Food processing plants produce wastewater containing vegetable peels, fruit cores, pulp, and other organic solids. Traditional pumps often clog, resulting in downtime and maintenance costs. Cutting sewage pumps can:

- Shred fibrous vegetable and fruit waste.

- Ensure smooth pumping of wastewater to treatment tanks or sewer systems.

- Maintain consistent flow rates for treatment or recycling processes.

2.2 Pulp and Paper Industry

The pulp and paper industry generates wastewater containing paper fibers, pulp residues, and sludges. Cutting sewage pumps are ideal for:

- Breaking down fibrous materials before pumping.

- Reducing the risk of clogging in pipelines and downstream equipment.

- Supporting recycling or treatment processes by homogenizing wastewater solids.

2.3 Textile and Garment Industry

Textile factories produce wastewater with cotton, polyester, and synthetic fibers that can tangle in standard pumps. Cutting sewage pumps:

- Slice fibers into smaller pieces for smooth transport.

- Reduce maintenance frequency and prevent pump failures.

- Enable better downstream treatment and filtration of wastewater.

2.4 Chemical and Pharmaceutical Industry

These sectors often handle wastewater containing solid residues, plastic granules, or chemical precipitates. Cutting sewage pumps help by:

- Preventing blockage caused by solid particles.

- Maintaining precise flow control for treatment and neutralization processes.

- Supporting compliance with environmental regulations regarding effluent quality.

3. Agricultural and Livestock Operations

Agriculture and livestock production generate wastewater with high solid content, including straw, feed residues, animal waste, and bedding materials. Handling this wastewater efficiently is crucial to prevent environmental contamination and maintain sanitation standards.

3.1 Livestock Farms and Manure Management

Livestock farms produce slurry with a mixture of liquid manure, bedding, and feed residues. Cutting sewage pumps:

- Shred solid materials before pumping to storage tanks or treatment systems.

- Prevent clogging in pipelines and equipment.

- Improve slurry homogenization for fertilization or biogas production.

3.2 Agricultural Processing Facilities

Facilities that process fruits, vegetables, grains, or other crops generate wastewater containing fibrous residues and seeds. Cutting sewage pumps:

- Facilitate smooth wastewater transport to treatment systems.

- Reduce the risk of blockages in pipelines.

- Enable reuse or recycling of water in processing operations.

4. Construction and Mining Industries

The construction and mining sectors generate wastewater containing sand, gravel, rocks, and debris. Traditional pumps are often inadequate for handling these coarse solids. Cutting sewage pumps are used for:

- Dewatering Construction Sites: Shredding and pumping slurry with soil, sand, and debris.

- Mining Operations: Handling tailings, slurry, and process water containing solid particles.

- Tunnel and Underground Projects: Managing wastewater containing construction debris.

By cutting and pumping mixed solid-laden water, these pumps ensure continuous operations and reduce wear on downstream equipment.

5. Marine and Shipboard Applications

Ships, offshore platforms, and marine vessels produce sewage containing fibrous waste, plastics, and food residues. Cutting sewage pumps are particularly valuable in marine applications because:

- They prevent clogging in sewage treatment systems onboard.

- Ensure compliance with international marine wastewater disposal regulations.

- Handle wastewater from kitchens, toilets, and machinery efficiently.

In addition, marine cutting sewage pumps are often designed to withstand harsh conditions, including saltwater exposure and vibration.

6. Advantages of Cutting Sewage Pumps Across Industries

Several factors make cutting sewage pumps preferable over standard sewage pumps in industries with solid-laden wastewater:

6.1 Clog Prevention

The integrated cutting mechanism shreds solids and fibers, preventing pipeline blockages and ensuring uninterrupted operation.

6.2 Reduced Maintenance

By minimizing clogging and mechanical stress, cutting sewage pumps reduce maintenance requirements, downtime, and operational costs.

6.3 Enhanced Flow Efficiency

Shredded solids are easier to pump, improving flow consistency and enabling smoother operation in treatment systems.

6.4 Versatility

Cutting sewage pumps can handle a wide range of wastewater types, from fibrous organic material to industrial sludge and construction slurry.

6.5 Compliance with Regulations

Efficient handling of solid-laden wastewater helps industries meet environmental regulations regarding effluent quality and disposal.

7. Emerging Trends in Cutting Sewage Pump Technology

As industries face stricter environmental regulations and increasing wastewater volumes, cutting sewage pump technology is evolving:

- Advanced Blade Designs: Improved cutting blades handle tougher solids and reduce wear.

- Corrosion-Resistant Materials: Pumps made from stainless steel or coated alloys extend lifespan in aggressive wastewater conditions.

- Integrated Monitoring: Sensors and smart controls help detect blockages, monitor motor performance, and optimize pump operation.

- Energy Efficiency: Modern cutting sewage pumps are designed for lower energy consumption while maintaining high throughput.

These innovations further expand the applicability and reliability of cutting sewage pumps across industries.

Conclusion

Cutting sewage pumps are indispensable in industries where wastewater contains solid particles, fibrous materials, or debris. The industries that benefit most from these pumps include:

- Municipal and Urban Wastewater Treatment: For handling raw sewage and stormwater efficiently.

- Industrial Wastewater Management: Particularly in food and beverage, pulp and paper, textile, chemical, and pharmaceutical sectors.

- Agriculture and Livestock Operations: Managing slurry, manure, and crop processing wastewater.

- Construction and Mining: Pumping debris-laden water from sites and tailings.

- Marine and Shipboard Applications: Ensuring effective sewage management on vessels and offshore platforms.

The main advantages of cutting sewage pumps—clog prevention, reduced maintenance, enhanced flow efficiency, versatility, and compliance with environmental regulations—make them essential for modern wastewater management. As technology advances, these pumps are becoming more durable, energy-efficient, and capable of handling even the toughest wastewater challenges.

Industries that adopt cutting sewage pumps can expect improved operational reliability, reduced downtime, and better environmental compliance, making these pumps a key investment in sustainable and efficient wastewater management.

Related Products

-

Horizontal pipeline pump

Cat:Pipeline Pump

ISW series single-stage single-suction horizontal centrifugal pumps ar...

See Details -

Ordinary sewage pump

Cat:Sewage Pump

1. Our WQ-type general sewage pump adopts a large flow channel anti-cl...

See Details -

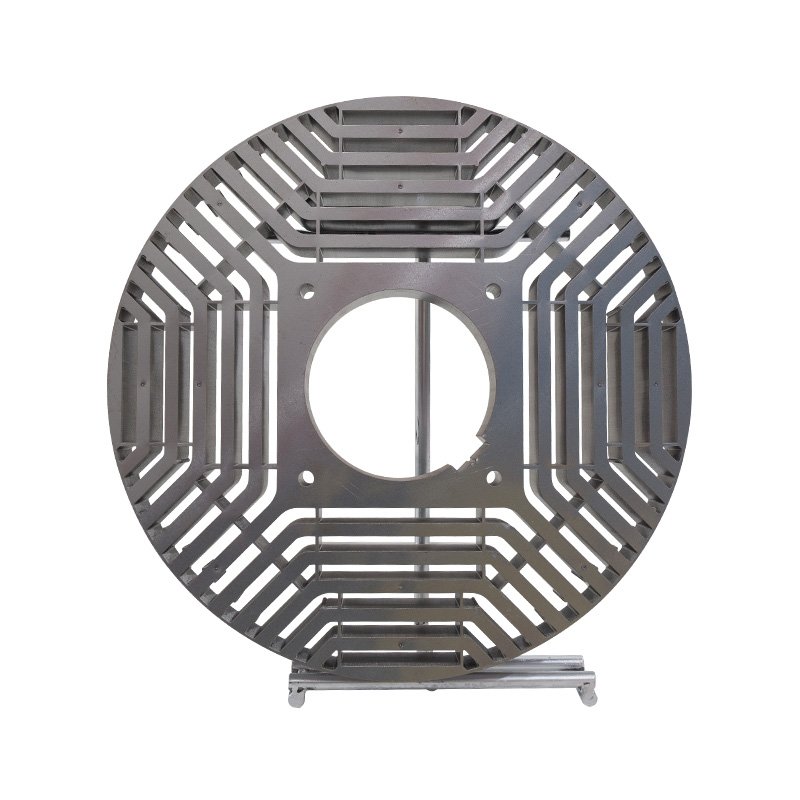

Sewage pump hanging cover

Cat:Sewage Pump Accessories

Installed on the upper part of the sewage pump unit, it is used for li...

See Details -

LG multi-stage pump middle section

Cat:LG Multi-stage Pump Accessories

The middle section is the main part of the pump body, responsible for ...

See Details -

LG multi-stage pump guide vane

Cat:LG Multi-stage Pump Accessories

A guide vane is a guiding device located at the impeller inlet that gu...

See Details -

LG multi-stage pump water bearing gland

Cat:LG Multi-stage Pump Accessories

Water bearing gland is the gland for fixing the water bearing, which s...

See Details -

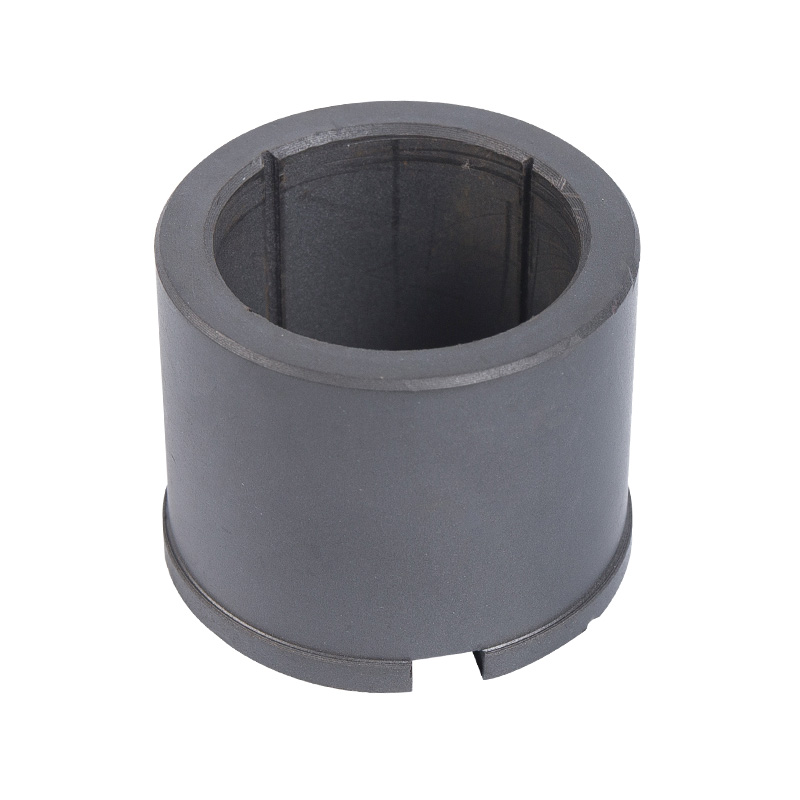

LG multi-stage pump water bearing

Cat:LG Multi-stage Pump Accessories

Water bearings are a special type of bearings commonly used in multi-s...

See Details -

Vertical motors

Cat:Ordinary Electric Motor

A conventional fixed-speed motor whose operating speed is usually cons...

See Details -

B14/B5 Vertical inverter motor

Cat:Inverter Electric Motor

A type of adjustable speed motor that can control the speed of the mot...

See Details -

Permanent magnet core stator and rotor

Cat:Electric Motor Accessories

A type of rotor core that uses a permanent magnet material to achieve ...

See Details

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

-

+86-0563-2251312

-

+86-0563-2251311

-

+86-139 6620 0379

-

-

No.43 Guohua Road, Guangde Economic Development Zone, Xuancheng City, Anhui Province, China