- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

Web Menu

- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

Product Search

Exit Menu

What Are the Typical Applications of LG Multistage Centrifugal Pumps in HVAC Systems?

Introduction: Role of LG Multistage Centrifugal Pumps in HVAC

LG multistage centrifugal pumps are widely utilized in HVAC (Heating, Ventilation, and Air Conditioning) systems due to their ability to handle high pressures, variable flow rates, and continuous operation. These pumps ensure efficient water circulation in both chilled water and hot water systems, contributing to optimal temperature control, energy savings, and reliable system performance. Understanding their typical applications in HVAC helps engineers select the right pump and optimize system design.

Chilled Water Circulation in Cooling Systems

In large commercial or industrial buildings, chilled water systems are essential for air conditioning. LG multistage centrifugal pumps provide the necessary flow and pressure to circulate chilled water from central chillers to air handling units (AHUs) and fan coil units (FCUs).

Primary and Secondary Pumping Loops

These pumps are often installed in both primary and secondary loops. The primary loop ensures constant flow through the chiller evaporators, while secondary pumps distribute water to different floors or zones, compensating for pressure losses and maintaining consistent cooling performance.

Variable Flow Applications

LG multistage pumps can handle variable flow requirements using variable frequency drives (VFDs). This flexibility allows HVAC systems to adjust water flow based on real-time cooling demand, improving energy efficiency and reducing operational costs.

Hot Water Circulation in Heating Systems

For hydronic heating systems, these pumps circulate hot water from boilers to radiators, fan coils, or underfloor heating loops. Their multistage design ensures sufficient head pressure to overcome friction losses in long piping networks.

High-Rise Building Applications

In high-rise buildings, water must be pumped to multiple floors at consistent pressure. LG multistage centrifugal pumps, with their high-pressure capabilities, ensure reliable hot water delivery without pressure fluctuations.

Zoned Heating Systems

These pumps support zoned heating by providing controlled flow rates to different areas of a building. By integrating with temperature sensors and VFDs, the system can adjust flow per zone, enhancing comfort and reducing energy consumption.

Booster Applications in HVAC

LG multistage pumps are ideal as booster pumps to maintain system pressure in extensive piping networks or remote sections of HVAC installations.

Maintaining System Pressure

Booster pumps ensure consistent pressure at terminal units, compensating for pressure drops caused by long pipelines, valves, or multiple fittings. This guarantees that all parts of the HVAC system receive adequate water flow for efficient operation.

Integration with Control Systems

LG pumps can be integrated with building management systems (BMS) to monitor pressure, flow, and energy usage. This allows automated adjustments for energy optimization and real-time performance tracking.

Cooling Tower and Condenser Water Applications

Multistage centrifugal pumps are also employed in circulating condenser water between cooling towers and chillers. They provide the high head required to move water through the cooling tower fill media, heat exchangers, and long piping runs efficiently.

Energy-Efficient Operation

By selecting appropriate pump curves and using VFDs, HVAC engineers can optimize pump operation for energy efficiency while maintaining required flow rates and head pressures.

Preventing Cavitation and Vibration

Proper pump selection and installation prevent cavitation, which can damage impellers and reduce efficiency. LG multistage pumps offer stable operation with minimal vibration when correctly sized and installed.

Typical Installation Configurations

LG multistage pumps can be installed horizontally or vertically, depending on space constraints and system design requirements.

- Horizontal inline pumps for compact installations and easy maintenance access.

- Vertical multistage pumps for limited floor space and deep suction lift applications.

- Multiple pump sets in parallel for redundancy, energy savings, and peak load handling.

Maintenance and Operational Best Practices

Proper maintenance ensures the longevity and efficiency of LG multistage centrifugal pumps in HVAC systems.

- Regular inspection of bearings, mechanical seals, and coupling alignment.

- Monitoring vibration and noise to detect early signs of wear or misalignment.

- Ensuring proper water quality and filtration to prevent corrosion and scale buildup.

- Following manufacturer-recommended lubrication schedules and replacement intervals.

Conclusion: Maximizing HVAC Performance with LG Pumps

LG multistage centrifugal pumps play a critical role in HVAC systems by providing reliable water circulation, high head pressure, and adaptable flow rates. Their applications include chilled water distribution, hot water heating loops, booster operations, and condenser water circulation. By understanding typical use cases, selecting appropriate pump models, and adhering to maintenance best practices, engineers can ensure energy efficiency, system reliability, and long-term operational performance. Proper integration with control systems further enhances system optimization and contributes to overall building comfort and sustainability.

Related Products

-

Pipe pump cover

Cat:Pipeline Pump Accessories

The pump cover is used to tighten and seal. The pump cover ensures tha...

See Details -

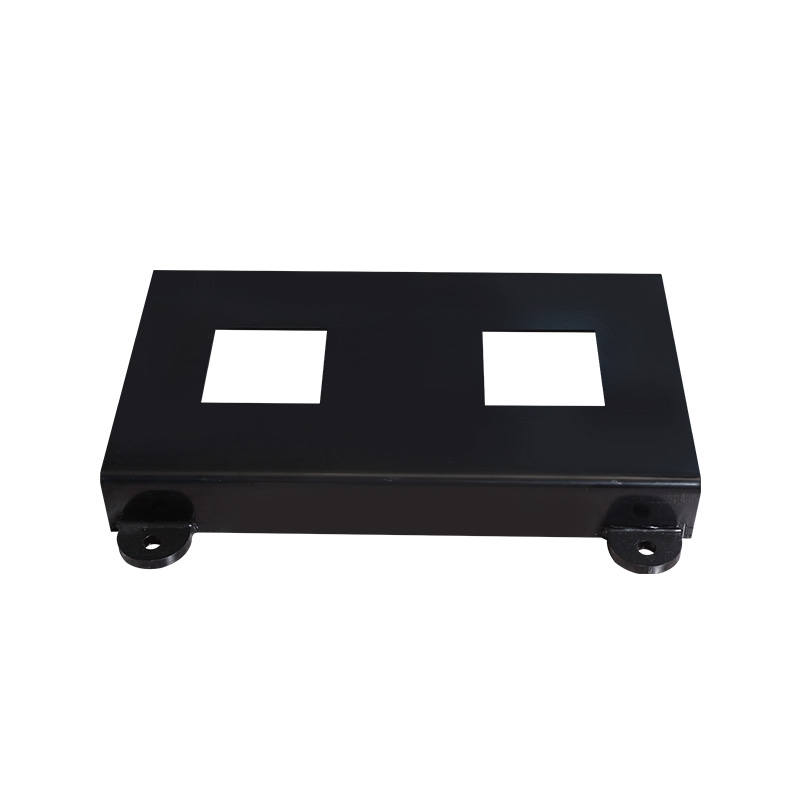

Pipe pump horizontal base

Cat:Pipeline Pump Accessories

The pump base serves to support and secure the pump casing. Horizontal...

See Details -

Ordinary sewage pump

Cat:Sewage Pump

1. Our WQ-type general sewage pump adopts a large flow channel anti-cl...

See Details -

Cutting sewage pump

Cat:Sewage Pump

Cutting sewage pump is a kind of sewage pump, also called cutting pump...

See Details -

LG multi-stage pump water inlet section

Cat:LG Multi-stage Pump Accessories

The inlet section is the inlet portion of the pump and is responsible ...

See Details -

LG multistage pump cast iron impeller

Cat:LG Multi-stage Pump Accessories

Cast iron impeller is one of the key components of the pump, which pre...

See Details -

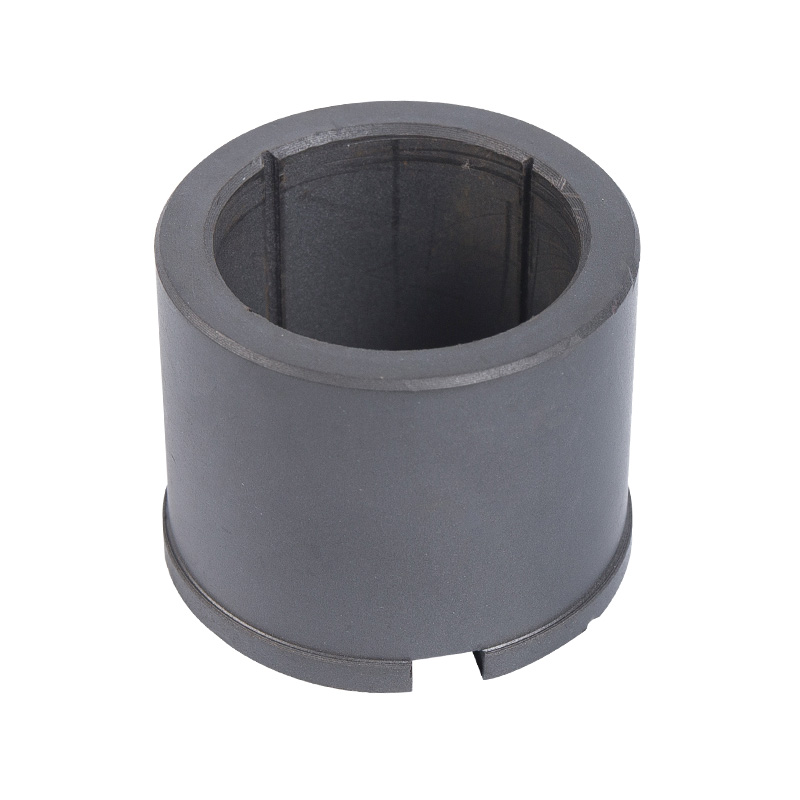

LG multi-stage pump water bearing

Cat:LG Multi-stage Pump Accessories

Water bearings are a special type of bearings commonly used in multi-s...

See Details -

B3/B35 Horizontal inverter motor

Cat:Inverter Electric Motor

Also known as base mounting, the motor is connected to the mounting da...

See Details -

Finished rotor

Cat:Electric Motor Accessories

The rotor of a motor refers to the rotating part, which contains the r...

See Details -

Cooling Tower Circulation Pump

Cat:Cooling Tower Circulation Pump

The cooling tower circulation pump is key equipment in the cooling tow...

See Details

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

-

+86-0563-2251312

-

+86-0563-2251311

-

+86-139 6620 0379

-

-

No.43 Guohua Road, Guangde Economic Development Zone, Xuancheng City, Anhui Province, China