- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

Web Menu

- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

Product Search

Exit Menu

Is Your Industrial Flow System Leaking Efficiency? The Power of the Horizontal Pipeline Pump

In the vast network of industrial plants, refineries, and large-scale HVAC systems, the consistent and efficient movement of fluids is the lifeblood of operations. Yet, many facilities rely on pumps that are misappied, inefficient, or require excessive maintenance, leading to costly downtime and energy waste. Could a fundamental piece of equipment be holding your entire system back? For countless engineers, the solution to achieving reliable, low-maintenance flow lies in a workhorse of fluid dynamics: the Horizontal Pipeline Pump. But what makes this specific pump design so uniquely suited for in-line duties, and how can it optimize your process from both a performance and economic standpoint? This guide delves into the critical role of the horizontal pipeline pump and its power to streamline your operations.

The In-Line Workhorse: What is a Horizontal Pipeline Pump?

A horizontal pipeline pump, often referred to as an inline pump, is a centrifugal pump designed to be installed directly within a pipeline. Its defining feature is its horizontal orientation, with the suction and discharge flanges aligned on the same horizontal plane. This allows the pump to be bolted directly into the existing pipe run, eliminating the need for complex baseplates, concrete foundations, or extensive pipe modifications. Engineered for seamless integration, this design is the go-to choice for a wide range of applications where space is at a premium and installation simplicity is paramount.

Engineered for Efficiency: Key Advantages Over Other Configurations

Why choose a horizontal pipeline pump over other types? The benefits are rooted in its practical, purpose-driven design:

- Space-Saving Installation: The most significant advantage. By mounting directly in the pipe, these pumps have an exceptionally small footprint. They free up valuable floor space in crowded pump rooms, eliminating the need for the large dedicated footprint required by end-suction pumps with their associated baseplates and alignment needs.

- Simplified Maintenance and Reduced Downtime: Many horizontal pipeline pumps feature a back pull-out design. This allows the entire rotating assembly—including the impeller, shaft, and bearings—to be removed for service without disconnecting the pump casing from the pipeline. This dramatically reduces maintenance time and cost, getting your system back online faster.

- Robust and Reliable Performance: Designed to handle the axial and radial loads inherent in pipeline systems, these pumps are built for durability. They are ideal for high-flow, low-to-moderate head applications, providing a smooth, consistent flow that is essential for process stability.

- Versatility Across Industries: The standardized flange design (e.g., ANSI or DIN) ensures easy integration into existing systems. They are employed in a massive range of duties, from transferring water, chemicals, and hydrocarbons in industrial plants to circulating hot or chilled water in large commercial HVAC systems.

Where It Excels: Prime Applications for Horizontal Pipeline Pumps

The horizontal pipeline pump is the undisputed champion for specific, critical roles:

- Industrial Process Transfer: Moving process fluids like water, solvents, oils, and mild chemicals from one stage of production to another within a plant.

- Boiler Feed and Circulation: Providing a reliable flow of water to industrial boilers and handling hot water circulation loops.

- Large-Scale HVAC Systems: Serving as the primary circulation pumps for chilled water in air conditioning systems and hot water in heating systems for large buildings, hospitals, and campuses.

- Water Supply and Distribution: Boosting pressure in municipal water lines, irrigation systems, and industrial water supply networks.

- Reverse Osmosis (RO) Systems: Acting as the high-pressure feed pump that pushes water through RO membranes.

Selecting the Right Pump: Critical Considerations

To maximize the benefits, it’s crucial to select the right pump for your specific duty. Key factors include:

- Material of Construction: The pump materials must be compatible with the fluid being pumped to avoid corrosion. Common choices include cast iron for water, stainless steel for chemicals, and bronze for seawater.

- Flow Rate and Head: Accurately determining your system’s required flow (e.g., GPM or m³/h) and total dynamic head (TDH) is essential for selecting a pump that operates efficiently at its Best Efficiency Point (BEP).

- Temperature and Pressure Ratings: Ensure the pump’s design can handle the fluid temperature and system pressure.

- Seal Type: Choose between mechanical seals (more efficient, less maintenance) or packing (for abrasive fluids) based on the application.

The Foundation of a Streamlined System

In the world of industrial fluid management, the horizontal pipeline pump represents a perfect fusion of simplicity, reliability, and efficiency. It is a solution designed not to complicate, but to integrate—a component that becomes a seamless, powerful part of your process flow.

Related Products

-

TD high-efficiency and energy-saving circulating pump cast iron impeller

Cat:TD High-efficiency And Energy-saving Circulating Pump Accessories

TD Energy Efficient Circulation Pump Cast Iron Impeller is an importan...

See Details -

Vertical pipeline pump

Cat:Pipeline Pump

ISG series single-stage single-suction vertical centrifugal pump is a ...

See Details -

Vertical pipeline pump body

Cat:Pipeline Pump Accessories

The pump body consists of two main parts: suction chamber and pressure...

See Details -

Horizontal pipeline pump body

Cat:Pipeline Pump Accessories

The pump body consists of two main parts: suction chamber and pressure...

See Details -

Pipe pump cover

Cat:Pipeline Pump Accessories

The pump cover is used to tighten and seal. The pump cover ensures tha...

See Details -

Pipeline pump B14 pump cover

Cat:Pipeline Pump Accessories

The pipeline pump B14 pump cover is a specific type of pump cover for ...

See Details -

LG multi-stage pump water inlet section

Cat:LG Multi-stage Pump Accessories

The inlet section is the inlet portion of the pump and is responsible ...

See Details -

LG multi-stage pump motor bracket

Cat:LG Multi-stage Pump Accessories

Motor bracket is a support part used to fix the motor and connect the ...

See Details -

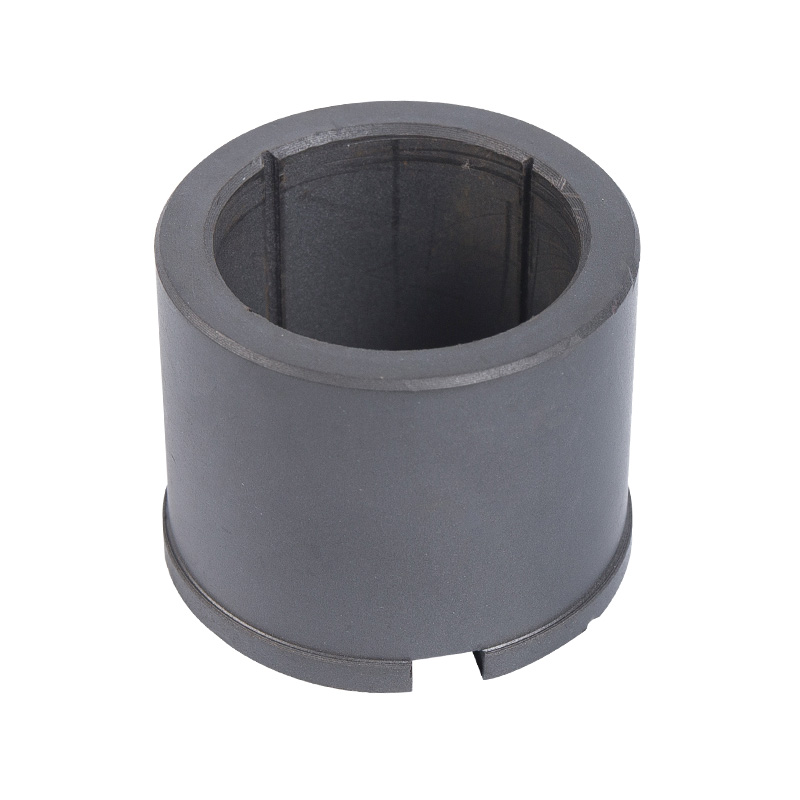

LG multi-stage pump water bearing

Cat:LG Multi-stage Pump Accessories

Water bearings are a special type of bearings commonly used in multi-s...

See Details -

LG multi-stage pump seal gland

Cat:LG Multi-stage Pump Accessories

The machine seal gland is a component that encloses the machine seal u...

See Details

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

-

+86-0563-2251312

-

+86-0563-2251311

-

+86-139 6620 0379

-

-

No.43 Guohua Road, Guangde Economic Development Zone, Xuancheng City, Anhui Province, China