- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

Web Menu

- Home

- About Us

- Products

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

- News

- Contact Us

Product Search

Exit Menu

What Is a Pipeline Pump and How Does It Work?

In many fields such as water supply, HVAC, fire protection, petrochemical, industrial circulation, etc., pipeline pump is a very common and important fluid conveying equipment. It is widely used in various conveying systems because of its convenient installation, compact structure and stable operation. Whether it is the water supply system of high-rise buildings or the liquid circulation system of complex factories, pipeline pumps play an irreplaceable role.

1. What is a pipeline pump?

Pipeline pump, also known as vertical pipeline centrifugal pump or inline pump, is a pump equipment designed to install the pump body coaxially with the pipeline axis. Its biggest feature is that the inlet and outlet diameters of the pump are the same and on the same axis. It can be incorporated into the pipeline system like ordinary pipelines without occupying additional space and foundation.

Features summary:

The pump body is installed coaxially with the pipeline, with a compact structure

Small footprint, easy installation and maintenance

Can be used in series to increase pressure

Applicable to a variety of media such as clean water, hot water, and lightly corrosive liquids

2. Working principle of pipeline pump

Basic principle:

The pipeline pump is a type of centrifugal pump (Centrifugal Pump), and its core principle is:

Use the centrifugal force generated by the high-speed rotation of the impeller to suck the liquid into the pump body and throw it out, thereby realizing the process of transporting the fluid from a low place to a high place.

The detailed workflow is as follows:

Start the motor: the drive shaft drives the impeller to rotate;

The liquid enters the center of the impeller (inlet);

The impeller rotates to generate centrifugal force: the liquid moves from the center to the outside along the blades;

The liquid is thrown out of the outer edge of the pump casing (outlet), and the kinetic energy is converted into pressure energy;

The liquid is transported to the target system along the pipeline.

Since the inlet and outlet are located on the same straight line, the liquid flows more smoothly and the energy loss is small, which is particularly suitable for medium and short distance and high-frequency transportation tasks.

3. Main structural components of pipeline pumps

Motor part: drives the pump shaft to rotate, usually a vertical motor;

Pump housing: encapsulates the impeller and guide part, usually made of cast iron or stainless steel;

Impeller: core component, determines flow and head;

Bearing and sealing system: ensures smooth operation of the shaft and prevents leakage;

Base/bracket: some models are equipped with an adjustable base for stable installation;

Cooling system (optional): used in high temperature conditions.

4. Common types of pipeline pumps

According to different uses and structures, pipeline pumps can be divided into the following types:

1. ISG pipeline centrifugal pump (single-stage clean water pump)

For clean water or liquids with physical and chemical properties similar to water

Applied to water supply, fire protection, and domestic water systems

2. IRG hot water pipeline pump

Suitable for high-temperature hot water circulation

Commonly used in boilers, water heating systems, and air conditioning systems

3. IHG chemical pipeline pump

Corrosion-resistant material, can transport corrosive liquids such as weak acids and alkalis

Used in chemical, pharmaceutical, and food industries

4. YG oil pump

Can transport diesel, gasoline, lubricating oil, etc.

Applicable to oil transportation systems

5. Advantages of pipeline pumps

Space saving Integrated installation with pipelines, suitable for small spaces or equipment-intensive areas

Easy installation No need to build a foundation, quickly connect to the original pipeline

Easy maintenance Some models support the "disassembly-free motor replacement" design

Low noise Most use vertical structure with low vibration

A variety of materials are available Stainless steel, cast iron, alloy steel, suitable for different media

Can be pressurized in series Multiple units in series can increase the head and meet the water supply needs of high-rise buildings

6. the key points of pipeline pump selection

When choosing a suitable pipeline pump, the following parameters should be considered:

Flow rate (m³/h): the required delivery volume of the system;

Head (m): the height or system pressure loss to be overcome;

Medium type and temperature: determine whether it is corrosion-resistant and high-temperature;

Pressure level: the maximum working pressure of the pipeline system;

Inlet and outlet diameter: match the existing pipeline system;

Control method: whether a frequency converter, constant pressure control, etc. are required;

Material requirements: whether all stainless steel, rubber lining, 316L, etc. are required;

Installation position: determine whether it can be installed vertically or horizontally.

7. Frequently Asked Questions (FAQs)

Q1: Can pipeline pumps be installed horizontally?

A: Most pipeline pumps are designed for vertical installation, but some models (such as horizontal pipeline pumps) can be installed horizontally, and the manufacturer's specifications need to be consulted.

Q2: Can it convey liquids with particles or high viscosity?

A: It is generally not recommended to transport liquids containing solid particles, otherwise the impeller is easily worn. You can consider self-priming pumps or mud pumps.

Q3: How to extend the service life of pipeline pumps?

A: Regularly check the shaft seal and bearing lubrication to ensure that no air enters the system to avoid dry operation.

As one of the core equipment in modern fluid transportation systems, pipeline pumps play an indispensable role in urban buildings, industrial systems and public infrastructure with their compact structure, stable operation and convenient installation. Through reasonable selection, correct installation and scientific maintenance, pipeline pumps can not only effectively improve system efficiency, but also save a lot of operating costs.

Related Products

-

Vertical TD high-efficiency and energy-saving circulation pump body

Cat:TD High-efficiency And Energy-saving Circulating Pump Accessories

Vertical TD Energy Efficient Circulating Pump Pump Body is the shell o...

See Details -

TD high-efficiency and energy-saving circulating pump cast iron impeller

Cat:TD High-efficiency And Energy-saving Circulating Pump Accessories

TD Energy Efficient Circulation Pump Cast Iron Impeller is an importan...

See Details -

TD high efficiency and energy saving circulating pump pump shaft

Cat:TD High-efficiency And Energy-saving Circulating Pump Accessories

The pump shaft is the component that connects the motor to the impelle...

See Details -

Horizontal pipeline pump

Cat:Pipeline Pump

ISW series single-stage single-suction horizontal centrifugal pumps ar...

See Details -

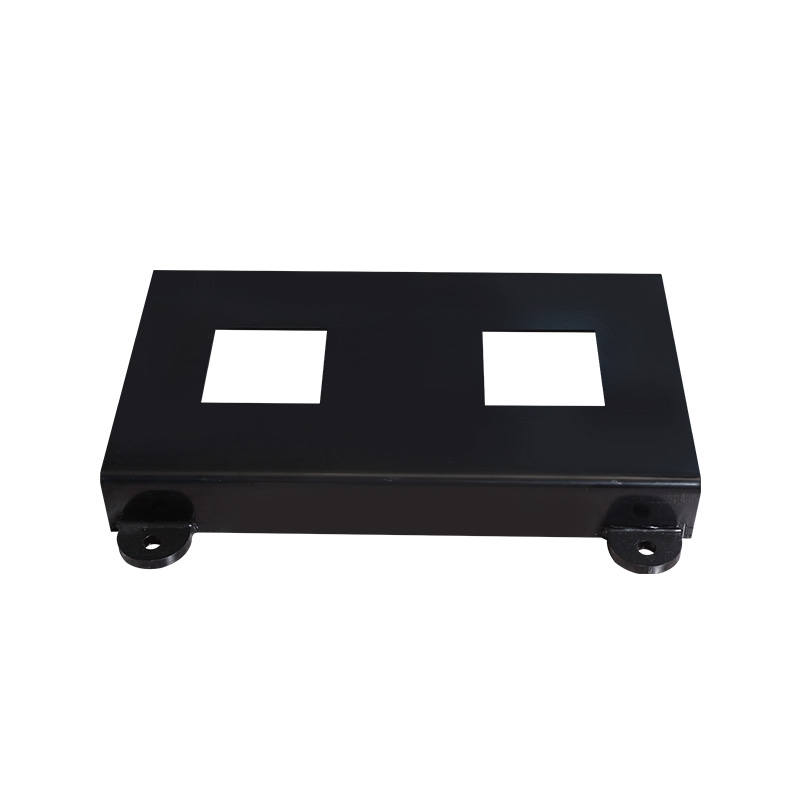

Pipe pump horizontal base

Cat:Pipeline Pump Accessories

The pump base serves to support and secure the pump casing. Horizontal...

See Details -

Cutting sewage pump

Cat:Sewage Pump

Cutting sewage pump is a kind of sewage pump, also called cutting pump...

See Details -

LG multi-stage pump coupling

Cat:LG Multi-stage Pump Accessories

Couplings are used to connect the pump shaft to the motor shaft for en...

See Details -

Horizontal motors

Cat:Ordinary Electric Motor

Also known as base mounting, the motor is connected to the mounting da...

See Details -

B3/B35 Horizontal inverter motor

Cat:Inverter Electric Motor

Also known as base mounting, the motor is connected to the mounting da...

See Details -

TD horizontal high-efficiency energy-saving circulation pump

Cat:TD High-efficiency And Energy-saving Circulating Pump

1.TD horizontal high-efficiency and energy-saving circulation pump is ...

See Details

- TD High-efficiency And Energy-saving Circulating Pump

- TD High-efficiency And Energy-saving Circulating Pump Accessories

- Pipeline Pump

- Pipeline Pump Accessories

- Sewage Pump

- Sewage Pump Accessories

- LG Multi-stage Pump

- LG Multi-stage Pump Accessories

- Cooling Tower Circulation Pump

- Electric Motor

- Electric Motor Accessories

-

+86-0563-2251312

-

+86-0563-2251311

-

+86-139 6620 0379

-

-

No.43 Guohua Road, Guangde Economic Development Zone, Xuancheng City, Anhui Province, China